Nylon Guard, Water Manifold & Water flow Regulator

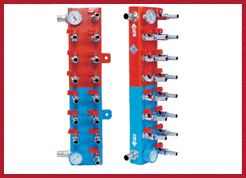

Water Manifold

Advantage :

Advantage :

» Simple & compact design.

» Suitable for moving plate & fix plate of

injection molding machine.

» Suitable for closed cooling circuits.

» Easy connection for supply & return cooling

circuit, by hose nipple.

» Easy operating by red & blue color code

for supply & return cooling circuit.

Technical Data And Range :

» Materials : MS or SS Pipe

» Pressure : 4 - 6 Bar

» Temperature : 0 °C -100 °C

» Valve : Brass Ball Valve

» Range : 4 - Stack to 30 - Stack

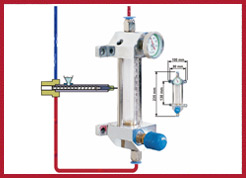

Hopper Cooling Water Flow Regulator

Standard Features :

Standard Features :

» Exact control of water flow in Hopper cing Jacket.

» Visual indication of water circulation in Hopper

cooling Jacket.

» Provide constant flow rate of cooling water.

Maintain Hopper zone Temperature for easy

feeding of Polymers.

» Provide consistence Extrusion of Polymers,

while process in Injection Moulding / Extruder /

Blow Moulding.

» Avoid Polymer sticking or Lump formulation

at feeding zone.

Technical Data :

» Body : Aluminum

» Visual Tube : Poly Carbonate

» Floater: Brass

» Clamp Bar: Brass with Plating

» Temp. Gauge : 0°C to 100°C

» Flow Rate : 10 LPM

Water Flow Regulator

Standard Features :

Standard Features :

» Simple & Compact design.

» Dependability due to robust contruction, all working parts including Brass Control Valves for supply & return.

» Precise control & perfect seal of each circuit.

» Easy connection for supply & return on the side of the manifold and of each cooling circuit by hose nipples. High durability, since all connections are made in metal.

» Easy cleaning of indicating pipes as they are quickly

removable via bayonet coupling.

» Suitable for open and closed cooling circuits.

Technical Data :

1. MEASURING RANGE:

» Per zone Brass cone (Standard) 10 L / min.

2. MATERIALS :

» Body : Alluminium

» Flow Tube : Poly Carbonate

» Pressure : 4-6 Bar

» Temp : 100C

» Throttle Valve Assembly : Brass